When the CPU is working, a lot of heat is generated. If the heat is not released in time, it may cause a crash in the slightest, and may burn the CPU in severe cases. The CPU radiator is used to dissipate heat for the CPU. The radiator plays a decisive role in the stable operation of the CPU. It is very important to choose a good radiator when assembling the computer.

Classification: Air-cooled radiator

Reason: CPU will generate a lot of heat when it is working

Note: It is very important to buy a good radiator

Radiator classification

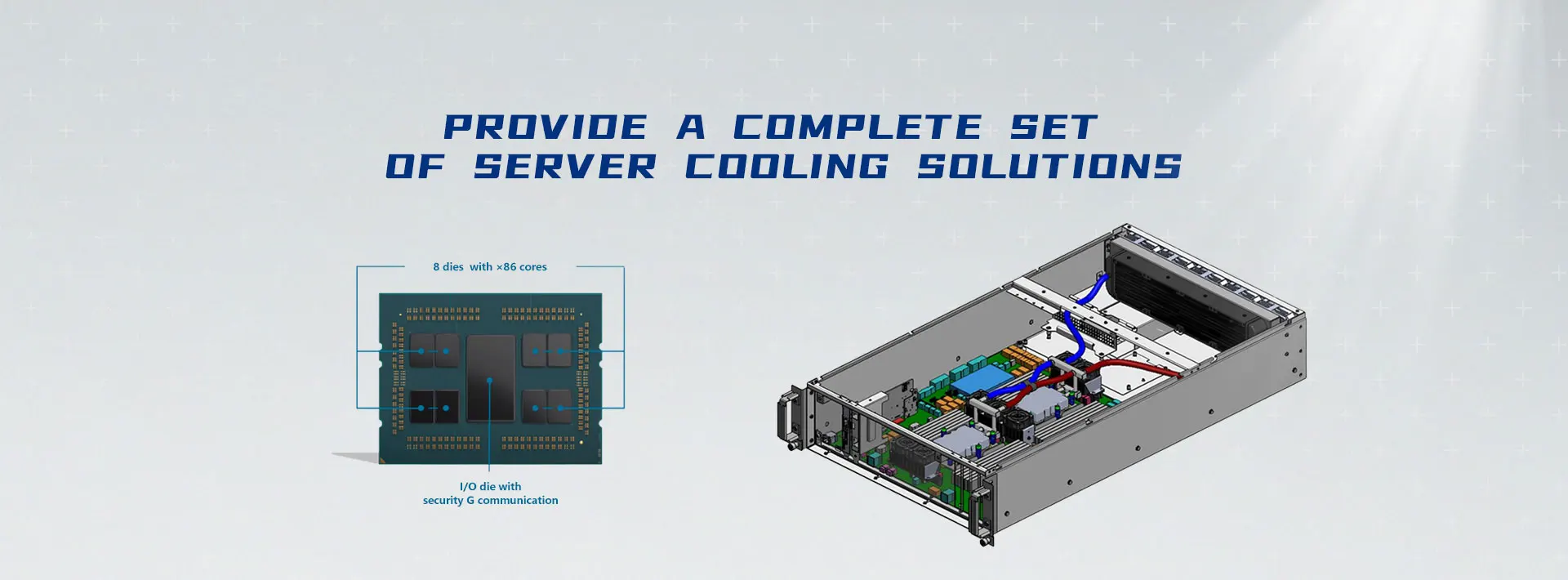

The CPU radiator can be divided into three types: air cooling, heat pipe and water cooling according to its heat dissipation mode.

Air-cooled radiator

Air-cooled radiator This is the most common type of radiator, including a cooling fan and a heat sink. The principle is to transfer the heat generated by the CPU to the heat sink, and then take the heat away through the fan. It should be noted that different types and specifications of CPU use different heat sinks. For example, AMD CPUs and Intel CPUs use different heat sinks. Intel 478-pin CPUs use different heat sinks and Intel 775-pin CPUs. .

Heat pipe radiator

The heat pipe radiator is a heat transfer element with extremely high thermal conductivity. It transfers heat through the evaporation and condensation of the liquid in the fully enclosed vacuum tube. Most of these fans are "air-cooled + heat pipe", with the advantages of both air-cooling and heat pipe, and have extremely high heat dissipation.

Water cooling radiator

The water-cooled radiator uses liquid to forcefully circulate under the drive of a pump to take away the heat of the radiator. Compared with air-cooling, it is quiet, stable in cooling, and less dependent on the environment.

Product Category

The radiator is divided into radiant radiator and convection radiator according to the heat exchange method. Convection radiators account for almost 100% of the heat dissipation by convection, and they are sometimes called "convection devices"; compared to convection radiators, other radiators use convection and radiation to dissipate heat at the same time, sometimes called "radiators".

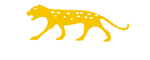

Radiators are divided into cast iron radiators, steel radiators and radiators of other materials according to their materials. Other material radiators include aluminum, copper, steel-aluminum composite, copper-aluminum composite, stainless steel-aluminum composite and enamel radiators.

How to choose a radiator

How to choose your own suitable radiator, it is very important to choose a good radiator. The following are some parameters about the radiator. Fan power: In general, the greater the power, the stronger the wind of the fan, and the better the heat dissipation effect.

Fan speed: Generally, the higher the fan speed, the greater the air volume it provides to the CPU, and the better the air convection effect will be. However, the extremely high speed will bring heat and aggravate the wear of the fan, so it is necessary to strike a balance between the two.

Heat sink material: The radiator widely uses low-cost and good heat dissipation aluminum alloy as the heat sink. At the same time, in order to improve the overall heat dissipation effect of the radiator, medium and high-end radiators use copper media with better heat dissipation effects where they are in contact with the CPU heat dissipation core.

Fan noise: refers to the sound made by the fan during operation, which is mainly affected by fan bearings and blades.

Fan exhaust volume: The fan exhaust volume is an important indicator to measure the performance of a fan. The angle of the fan blades and the speed of the fan are all decisive factors that affect the exhaust air volume of the cooling fan.

Nickel plating process

The method of plating a layer of nickel on metals or certain non-metals by electrolysis or chemical methods is called nickel plating. Nickel plating is divided into electroplating nickel and electroless nickel plating. Nickel electroplating is in an electrolyte composed of nickel salt (called main salt), conductive salt, pH buffer, and wetting agent. Metallic nickel is used for the anode, and the cathode is the plated part. Direct current is applied to the cathode (plated part). A uniform and dense nickel plating layer is deposited. Bright nickel is obtained from the bath with brightener, and dark nickel is obtained from the electrolyte without brightener. Electroless plating is also called electroless plating, and it can also be called autocatalytic plating. The specific process refers to: under certain conditions, the metal ions in the aqueous solution are reduced by the reducing agent and precipitated on the surface of the solid substrate.

(1) The characteristics and performance of electroplated nickel:

1. The stability of the electroplated nickel layer in the air is very high. Due to the strong passivation ability of metallic nickel, a very thin passivation film can be quickly formed on the surface, which can resist the corrosion of the atmosphere, alkali and certain acids. .

2. Electroplated nickel crystals are extremely small and have excellent polishing performance. The polished nickel coating can get a mirror-like gloss appearance, while maintaining its gloss for a long time in the atmosphere. Therefore, the electroplated layer is often used for decoration.

3. The hardness of the nickel plating layer is relatively high, which can improve the wear resistance of the surface of the product.

4. Nickel plating is used as a protective decorative coating. On the surface of steel, zinc die castings, aluminum alloys and copper alloys, it protects the base material from corrosion or plays a bright decorative role; it is also often used as an intermediate coating for other coatings, on top of it. Plating a thin layer of chromium, or plating a layer of imitation gold, its corrosion resistance is better and the appearance is more beautiful.

5. In electroplating, nickel electroplating has many excellent properties.

(2) Characteristics and performance of electroless nickel plating:

1. Thickness uniformity Uniform thickness and good throwing ability are a major feature of electroless nickel plating and one of the reasons why it is widely used. Electroless nickel plating avoids the uneven thickness of the electroplated layer due to uneven current distribution. During electroless plating, as long as the surface of the part is in contact with the plating solution, the components consumed in the plating solution can be replenished in time, and the thickness of the plating layer of the plating part is basically the same, even for grooves, gaps, and blind holes.

2. The plated parts will not permeate hydrogen, and there is no hydrogen embrittlement. There is no need to remove hydrogen after electroless nickel plating.

3. The functions of many materials and parts, such as corrosion resistance and high temperature oxidation resistance, are better than those of electroplated nickel.

4. It can be deposited on the surface of various materials, such as: steel nickel-based alloys, zinc-based alloys, aluminum alloys, glass, ceramics, plastics, semiconductors and other materials, thereby creating conditions for improving the performance of these materials.

5. There is no need for DC motors or control equipment required for general electroplating.

6. The heat treatment temperature is low. As long as the temperature is below 400℃, different corrosion resistance and wear resistance can be obtained after different holding time. Therefore, it is especially suitable for the functionality of parts with complex shapes and surface requirements for wear resistance and corrosion resistance. Plating etc.

Classification: Air-cooled radiator

Reason: CPU will generate a lot of heat when it is working

Note: It is very important to buy a good radiator

Radiator classification

The CPU radiator can be divided into three types: air cooling, heat pipe and water cooling according to its heat dissipation mode.

Air-cooled radiator

Air-cooled radiator This is the most common type of radiator, including a cooling fan and a heat sink. The principle is to transfer the heat generated by the CPU to the heat sink, and then take the heat away through the fan. It should be noted that different types and specifications of CPU use different heat sinks. For example, AMD CPUs and Intel CPUs use different heat sinks. Intel 478-pin CPUs use different heat sinks and Intel 775-pin CPUs. .

Heat pipe radiator

The heat pipe radiator is a heat transfer element with extremely high thermal conductivity. It transfers heat through the evaporation and condensation of the liquid in the fully enclosed vacuum tube. Most of these fans are "air-cooled + heat pipe", with the advantages of both air-cooling and heat pipe, and have extremely high heat dissipation.

Water cooling radiator

The water-cooled radiator uses liquid to forcefully circulate under the drive of a pump to take away the heat of the radiator. Compared with air-cooling, it is quiet, stable in cooling, and less dependent on the environment.

Product Category

The radiator is divided into radiant radiator and convection radiator according to the heat exchange method. Convection radiators account for almost 100% of the heat dissipation by convection, and they are sometimes called "convection devices"; compared to convection radiators, other radiators use convection and radiation to dissipate heat at the same time, sometimes called "radiators".

Radiators are divided into cast iron radiators, steel radiators and radiators of other materials according to their materials. Other material radiators include aluminum, copper, steel-aluminum composite, copper-aluminum composite, stainless steel-aluminum composite and enamel radiators.

How to choose a radiator

How to choose your own suitable radiator, it is very important to choose a good radiator. The following are some parameters about the radiator. Fan power: In general, the greater the power, the stronger the wind of the fan, and the better the heat dissipation effect.

Fan speed: Generally, the higher the fan speed, the greater the air volume it provides to the CPU, and the better the air convection effect will be. However, the extremely high speed will bring heat and aggravate the wear of the fan, so it is necessary to strike a balance between the two.

Heat sink material: The radiator widely uses low-cost and good heat dissipation aluminum alloy as the heat sink. At the same time, in order to improve the overall heat dissipation effect of the radiator, medium and high-end radiators use copper media with better heat dissipation effects where they are in contact with the CPU heat dissipation core.

Fan noise: refers to the sound made by the fan during operation, which is mainly affected by fan bearings and blades.

Fan exhaust volume: The fan exhaust volume is an important indicator to measure the performance of a fan. The angle of the fan blades and the speed of the fan are all decisive factors that affect the exhaust air volume of the cooling fan.

Nickel plating process

The method of plating a layer of nickel on metals or certain non-metals by electrolysis or chemical methods is called nickel plating. Nickel plating is divided into electroplating nickel and electroless nickel plating. Nickel electroplating is in an electrolyte composed of nickel salt (called main salt), conductive salt, pH buffer, and wetting agent. Metallic nickel is used for the anode, and the cathode is the plated part. Direct current is applied to the cathode (plated part). A uniform and dense nickel plating layer is deposited. Bright nickel is obtained from the bath with brightener, and dark nickel is obtained from the electrolyte without brightener. Electroless plating is also called electroless plating, and it can also be called autocatalytic plating. The specific process refers to: under certain conditions, the metal ions in the aqueous solution are reduced by the reducing agent and precipitated on the surface of the solid substrate.

(1) The characteristics and performance of electroplated nickel:

1. The stability of the electroplated nickel layer in the air is very high. Due to the strong passivation ability of metallic nickel, a very thin passivation film can be quickly formed on the surface, which can resist the corrosion of the atmosphere, alkali and certain acids. .

2. Electroplated nickel crystals are extremely small and have excellent polishing performance. The polished nickel coating can get a mirror-like gloss appearance, while maintaining its gloss for a long time in the atmosphere. Therefore, the electroplated layer is often used for decoration.

3. The hardness of the nickel plating layer is relatively high, which can improve the wear resistance of the surface of the product.

4. Nickel plating is used as a protective decorative coating. On the surface of steel, zinc die castings, aluminum alloys and copper alloys, it protects the base material from corrosion or plays a bright decorative role; it is also often used as an intermediate coating for other coatings, on top of it. Plating a thin layer of chromium, or plating a layer of imitation gold, its corrosion resistance is better and the appearance is more beautiful.

5. In electroplating, nickel electroplating has many excellent properties.

(2) Characteristics and performance of electroless nickel plating:

1. Thickness uniformity Uniform thickness and good throwing ability are a major feature of electroless nickel plating and one of the reasons why it is widely used. Electroless nickel plating avoids the uneven thickness of the electroplated layer due to uneven current distribution. During electroless plating, as long as the surface of the part is in contact with the plating solution, the components consumed in the plating solution can be replenished in time, and the thickness of the plating layer of the plating part is basically the same, even for grooves, gaps, and blind holes.

2. The plated parts will not permeate hydrogen, and there is no hydrogen embrittlement. There is no need to remove hydrogen after electroless nickel plating.

3. The functions of many materials and parts, such as corrosion resistance and high temperature oxidation resistance, are better than those of electroplated nickel.

4. It can be deposited on the surface of various materials, such as: steel nickel-based alloys, zinc-based alloys, aluminum alloys, glass, ceramics, plastics, semiconductors and other materials, thereby creating conditions for improving the performance of these materials.

5. There is no need for DC motors or control equipment required for general electroplating.

6. The heat treatment temperature is low. As long as the temperature is below 400℃, different corrosion resistance and wear resistance can be obtained after different holding time. Therefore, it is especially suitable for the functionality of parts with complex shapes and surface requirements for wear resistance and corrosion resistance. Plating etc.